Mobile & Internet

Delay in foundry biz assessment did more good than harm: MagnaChip CEO

NYSE-listed chipmaker head hints at positive results of evaluations

Semiconductor firm MagnaChip, which has made inroads in the US and South Korea, announced in February that it would proceed with the strategic evaluation process for its overall foundry business, including its Fab. 4 fabrication plant. The company said results of the evaluation could differ, such as a merger, strategic partnership or a joint venture, depending on the market conditions.

However, there has been no progress so far, with only rumors claiming that a merger deal with a local chip firm broke down due to the high asking price and the sluggish market.

To clarify the rumors, MagnaChip CEO Kim Young-Joon had a rare interview with some Korean media outlets on Sept. 26 in Seoul.

Kim, who joined the New York Stock Exchange-listed company in 2013, said the strategic evaluation is still on the right track, in contrast to some news reports, and the company will come up with satisfying results for the interested parties.

|

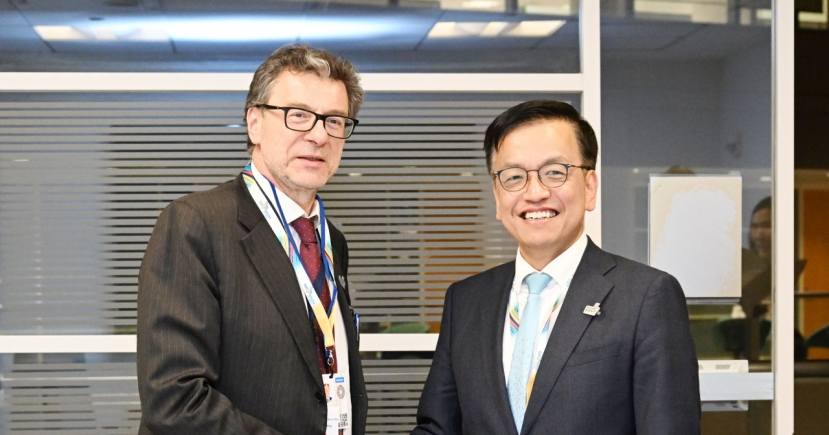

MagnaChip CEO Kim Young-Joon speaks in an interview with reporters on Sept. 26 in Seoul. (MagnaChip) |

“Over the past months, the company’s sales and margin have improved in our three business pillars, including the foundry biz, and they will likely gain further momentum,” CEO Kim said.

“I can say that the company has now more options to consider in the ongoing assessments.”

In the early days of the evaluation process, led by financial services firm JP Morgan, the sell-off of its foundry unit appeared to be the most likely choice.

The foundry division was considerd to have lost steam in terms of growth rate and return of investment. The company’s overall sales in the January-March period this year dropped to $157 million, down from $166 million in the first quarter last year. The foundry unit, in particular, posted a 25 percent quarterly decline to $57 million. Its related businesses, which accounted for 60-70 percent of the company’s overall sales in 2011, now takes up 35 percent.

Now with the foundry business seeing its sales and margin bounce back, however, the company seems to more actively consider a broader range of options, rather than just selling the unit.

Kim hinted that finding partners who are willing to make large investments in the capital intensive business is one possible option among others.

Running a foundry requires a large amount of capital. A factory like Fab. 4, located in Cheongju, North Chungcheong Province, requires approximately 1.5 trillion won ($1.25 billion) to build from the scratch even after deploying used fabrication devices.

He also denied rumors that the Cheongju plant, which produces chips based on 8-inch wafers, has been losing luster from potential bidders or investors since many of the latest factories utilize 12-inch wafers are more efficient and productive.

“We are now seeing an increasing demand for 8-inch-based products, such as MOSFET, IGBT and Super Junction, with the emergence of new businesses, like electric vehicle,” said Kim, noting the products are still state-of-the-art.

MOSFET, IGBT and Super Junction are electric components used to control the power for mobile, and consumer electronics.

The CEO also forecast there could be a supply shortage in the segment as building a new 8-inch fabrication factory will be limited, for some reasons, in China.

“As a result, the Cheongju plant and its products, most of which boast top-tier technology, will stand out in the market,” he said.

The Fab. 4 plant currently has a monthly production capacity of 82,000 wafers a month -- the eight-largest globally. With some new investments, the capacity could increase up to 100,000 a month, which will thrust the fab into the top 5.

Although it is listed on the New York Stock Exchange, most of the company’s manufacturing facilities and intellectual properties are located in Korea. The geopolitical factors make the company and its businesses more attractive as well since it is unaffected by the current US-China trade war, according to the CEO.

LG Semiconductor, which was later merged with Hyundai Semiconductor to become SK hynix, is the predecessor of MagnaChip. The NYSE-listed chipmaker was spun off in 2004.

By Kim Young-won (wone0102@heraldcorp.com)