Samsung

Samsung boosts investment in Austin chip plant for 4th industrial revolution

[THE INVESTOR] South Korea’s tech giant Samsung Electronics is preparing for the “fourth industrial revolution” by mass producing faster and more efficient chips for smart and connected devices with always-on displays, cementing its leadership in the global memory market.

As part of its latest move, the Korean chipmaker made around $1 billion worth of investments in its production facilities in Austin, Texas, as of this month. The facilities are operated for advanced system-on-chip products, which are supplied for mobile and other electronic devices.

|

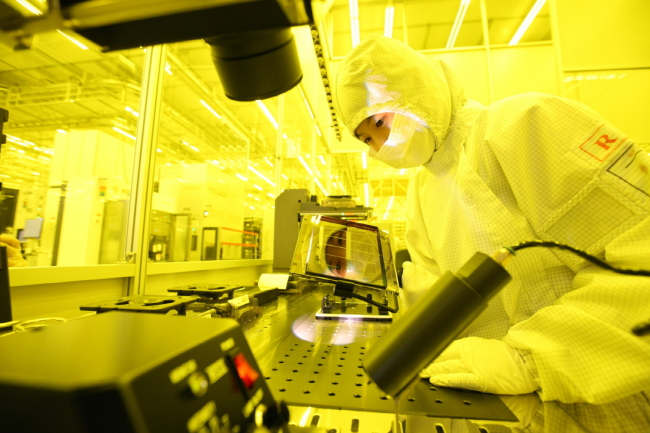

An employee works at a Samsung Electronics semiconductor fabrication line in Hwaseong, Gyeonggi Province. Samsung Electronics. |

Samsung Austin Semiconductor, the operator of Samsung’s chip production in the US, contributed $3.6 billion into the regional economy of central Texas in 2015, according to a local study there. The company also supported 10,755 jobs in the area and $498 million in annual salaries. Since its establishment in 1997, Samsung has invested more than $16 billion on the expansion and maintenance of its Austin facility.

The newest investment is interpreted as Samsung’s intention to enhance its system LIS chip business along with its powerful memory chip business, as it foresees growth in demand for various System-on-Chip products in the era of the fourth industrial revolution.

In order to support the production of faster and more efficient chips and processors, Samsung has unveiled a roadmap for a comprehensive foundry process technology, which aims to improve the process technology to more sophisticated levels.

Beyond the current second-generation 10-nanometer Fin FET process technology, Samsung plans to further develop an 8-nanometer process technology by this year, a 7-nanometer by 2018 and a 4-nanometer by 2020. The smaller the nanometer size, the more advanced chips with larger storage space will be.

“The inclusion of the process technologies above will enable an explosion of new devices that will connect consumers in ways never seen before,” said Yoon Jong-shik, executive vice president of the foundry business at Samsung Electronics at the Samsung Foundry Forum held in Santa Clara, US, in May.

US-based Qualcomm’s Snapdragon 835 processor is produced on Samsung’s 10-nanometer Fin FET process technology.

While continuing to invest in advancing the process technologies, Samsung is ramping up efforts to reinforce its No. 1 position in the memory market as well.

It announced earlier this month it had begun the mass production of 64-layer, 256-Gigabit V-NAND flash memory chips and would apply the cutting-edge technology to the company’s lineup of storage solutions for servers, PCs and mobile applications.

The Samsung 64-layer 3-bit 256-GB V-NAND features a data transfer speed of 1 gigabits per second, which is the fastest among currently available NAND flash memory. The new 64-layer V-NAND provides a more than 30 percent productivity gain compared to the 48-layer 256 GB V-NAND that preceded it.

Global demand for 3-D NAND flash chips is on the rise as the consumption of data on mobile devices is growing at an explosively rate. The global NAND flash market is forecast to rise 6.1 percent on average annually by 2020, according market researcher IHS Markit. Samsung is already the world’s largest NAND chip provider with a 36.7 percent market share.

The company will start operation of a new NAND chip plant in Pyeongtaek, Gyeonggi Province, at the end of this month, in order to respond to the growing demand and help ease the current short supply.

To solidify its leadership in the memory market, Samsung intends to expand production of the latest V-NAND chips to above 50 percent of its monthly NAND production by the end of the year, the company said.

Samsung also started mass-producing a processor designed exclusively for Internet of Things platforms, another major area of the upcoming fourth industrial revolution.

The tech giant’s processor is named “Exynos i T200,” designed to support secure mobile communications among IoT platforms. Samsung hopes to expand its presence in the global IoT industry with the new processor.

“The latest announcements of the mass production of the Exynos processor and 64-layer V-NAND flash chips are part of Samsung’s moves toward the next industrial revolution, considering growing consumption of massive data,” a Samsung official said.

By Song Su-hyun/The Korea Herald (song@heraldcorp.com)