Bio

From CMO to CDO, Samsung BioLogics wants it all

[THE INVESTOR] FRANKFURT -- Samsung BioLogics isn’t content being a contract manufacturing organization. Now, it wants to directly service global pharmaceutical companies with new medicines by pushing down prices without compromising on quality or supply.

“Our competitors are no longer other contractors. It’s the in-house manufacturing units of global biopharma companies that we’ll be up against,” Samsung BioLogics CEO Kim Tae-han told The Investor on the sidelines of the CPhI Worldwide Pre-Connect Congress in Frankfurt, Germany, on Oct. 23 after his keynote speech.

|

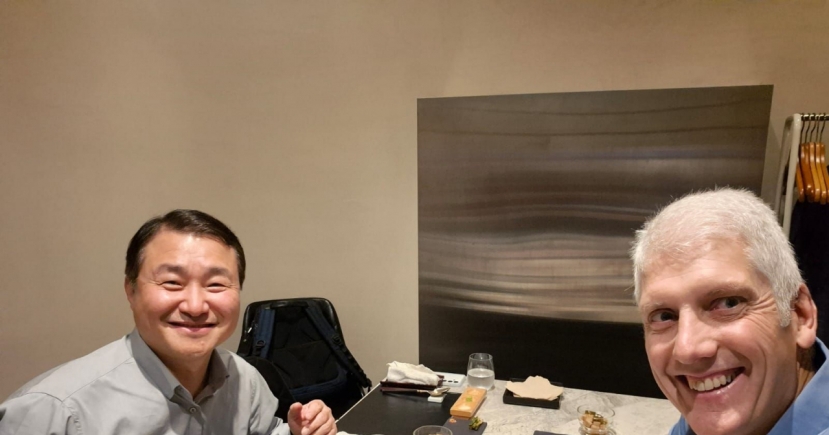

Samsung BioLogics CEO Kim Tae-han. |

Samsung BioLogics already is a contract development organization that takes home orders that originally would have gone to in-house units.

Making Kim’s vision possible is Samsung BioLogics’ third plant, which will spew out 362,000 liters to feature the world’s largest bio-pharmaceutical manufacturing capacity once it goes online. The volume is higher than that of existing market heavyweights such as Boehringer Ingelheim with 250,000 liters and Lonza with 260,000 liters.

Kim was confident about winning enough orders to run all three of its plants when the time comes for the commercialization of blockbuster drugs such as the treatment for Alzheimer‘s disease. Samsung BioLogics has already decided on the site for a fourth plant, for which construction may start as soon as companies developing Alzheimer’s disease therapy shows positive late-stage clinical trial results at around 2020.

“Ultimately, we want to become a game changer by undoing the perception that drug companies have to manufacture their own biologics,” said the CEO.

Currently, some 70 percent of global biologics drugs are manufactured in-house due to biopharma firms’ desires to control the supply chain and minimize the risk of complex manufacturing. Kim said that Samsung BioLogics could help these companies time and cost, along with offering capacity flexibility.

“We can resolve biopharma industry risks like excessive capital spending, while taking off up to seven years time when expanding manufacturing facilities,” he said.

With its third plant is expected to completed by November, the firm will cut down on the construction lead time to 29 months from the averag 48 months, which is about 40 percent less.

“No one really thought semiconductor outsourcing companies could develop so much as to achieve a market share of more than 50 percent of the global semiconductor production,” Kim said, adding that Samsung BioLogics hopes to duplicate the success of its tech affiliate, Samsung Electronics which started from similar roots.

The growing demand for CMO is another factor fueling the Korean biopharma company’s ambitions. According to figures from industry advisory group Results Healthcare, the global market for contract manufacturing organizations will reach US$105 billion by 2021 from US$71.5 billion in 2015. The figure is almost double the global semiconductor market value.

By Park Han-na (hnpark@heraldcorp.com)